INDUSTRIAL SECTOR

FOOD AND BEVERAGES

Automatización Avanzada S.A has experience in the automation and development of industrial process control systems from different sectors such as: food and beverages, paper, laboratories and others. Implementation and design of automation systems for production plants using state-of-the-art technologies and field buses for the acquisition of information, among these are intelligent instrumentation and conventional signals.

Our experience in industrial processes allows us to count with a work group specialized in solutions that guarantee answer in the shortest time, following high quality standards and our ISO9001certification to provide reliability to our customers.

Automation systems and process control of food and beverages

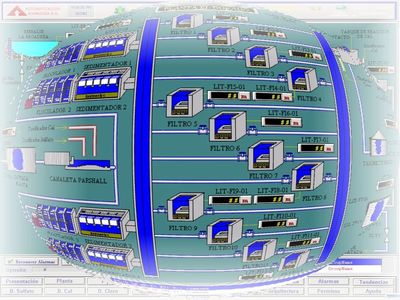

Automation Systems for production plants by means of the acquisition of the plant information by MODBUS field buses, PROFIBUS, ASI, INTERBUS, DEVICENET, FIELD BUS FUNDATION and other industrial buses through intelligent instrumentation or conventional signals.

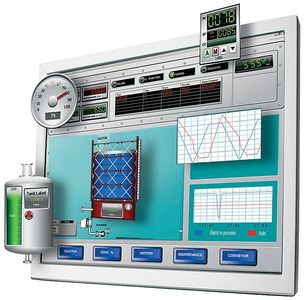

Our systems allow the handling of the production either by lots (batch), according to the ISA S88 standard that defines the models of reference for the implementation of control systems of processes by lots allowing high flexibility and reusability level, also the prescription handling.

Our systems allow a remote management, also the management of database

Design, programming, configuration, installation and launch of Supervisory Systems (SCADA and dialogue terminals)

From the supervision point of view, you can have one or several operation stations where the operator can visualize the process through animated deployments, take decisions like the Set Points sending, commands, emergency stops, change of product prescription in the line, etc.

Depending on the process to control, the system realizes the acquisition of analogous and digital signals, executes sequences and control loop and sends back commands and slogans to the process so that it carries out the required functions. Through communications links, it can interchange data with other subsystems or instrumentation and/or maneuver equipment, to obtain a distributed control system, in which the tasks and signals are distributed in an efficient and economic form.

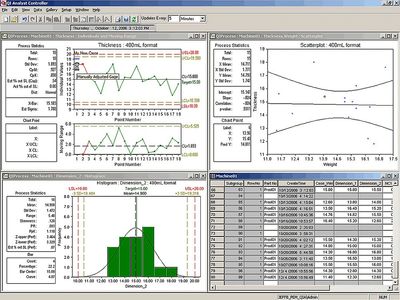

Systems for quality control in production lines

The system can generate reports and databases in several formats used in the computer science industry, allowing posterior consultation of the historical process data. These databases can be shared by applications of administrative level to take quality calculations, production and inventories.

Industrial Information Systems and Automation

We develop and we implement Industrial Software and computer science solutions for the manufacturing industry (MES implementation system), that eliminate the communication breach that commonly exists between the floor plant information and the one of the business. We count on diverse solutions of industrial software, among which emphasize:

- Floor Control (Shop Floor Control): data integration from the production unit to the management level, allowing the access to the information from industrial environments to administrative environments ERP (SAP, JD Edwards).

- Production Efficiency Measuring OEE and other indicators: There are numerous performance indicators that allow a company to know how well it performs in different aspects from the manufacture processes. One of them is called the OEE indicator that measures the efficiency in the productivity of an equipment or production line, measure the current quality index (Amount of good pieces/Amount of total pieces)

- SCADA Systems: The great majority of the productive processes require that the critical variables of a process remain as stable as possible. This is why graphics of his behavior over time must be obtained. Normally for this purpose, software denominated SCADA is used (Supervisory Control And Data Acquisition) through which tendency graphics are presented and it is allowed to analyze the behavior of the processes.

- Traceability (Tracking):

The traceability in the manufacture processes allows the company to know in all moment the location of the production orders, lots or pieces inside (of these processes) of the productive process.

Thus, it is possible to be known at any moment:

- Date and beginning/end Hour of the lot in each stage of the productive process.

- In what stage of the process is each lot or piece.

- Results of quality control tests made to the lot.

- Lots or pieces that were remanufactured or repaired.

- Lots or scrap pieces.

Política de Cookies

Este sitio web utiliza cookies, al seguir utilizando este sitio, aceptas nuestro uso de cookies.