SOLAR ENERGY PHOTOVOLTAIC SYSTEMS

The photovoltaic systems require to operate for a long time and continuously, that is why Automatización Avanzada S.A. has developed a portfolio to meet the development of these renewable energies

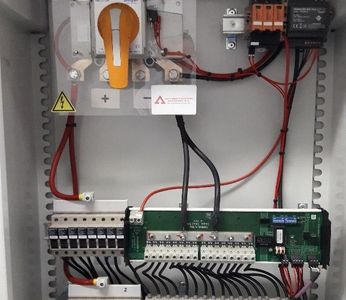

Grouping Board (Combiner Box) with RETIE certification required by the Ministry of Mines and Energy, with connection for systems of 1500 Volts of direct current, hermiting in solar panel technology.

Our solution takes the experience and expertise of the global manufacturer WEIDMULLER, with the gamma of its cutting-edge products in compliance with the highest standards of global value.

We design and manufacture these grouping boards (Combiner Box) for the different of a photovoltaic system, this solution allows the grouping of strings and their respective connection with the inverters or electrical groupers of level 2, this solution can include monitoring functions to provide information valuable for the maintenance and operation of the solution.

ELECTRICAL PANELS

Automatizacion Avanzada S.A. counts on a quality policy to guarantee the satisfaction of its clients. Our management quality system is under the alignments of the ISO 9001 norm, which makes to the constant improvement of our processes and services.

We are specialists in the design and manufacture of boards and electrical cabinets of low tension, we provide average tension cells, respecting and fulfilling national and international norms, applicable in diverse sectors, which go from the electrical use in the domiciliary areas, industrial and electrical energy distribution among others.

Design and supply of Electrical Substations

Automatizacion Avanzada realizes the design under ISO 9001 quality standards, of its electrical substation according to the needs of the end

Once the requirements have been delimited, we can provide the solution of electrical substations of Average and Low Tension.

Our solution provides:

- Modular units with SF6 switches

- Protection Electronic relays

- Multifunctional meterS

- Energy Counters

- Re-connectors

- Sectionalizers

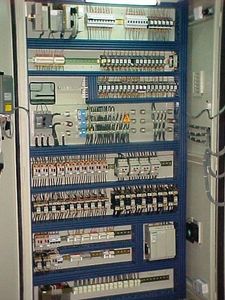

Panels Design, Power Distribution Center

We design, manufacture and supply under ISO 9001 quality standards, following Nema or IEC alignments for the mechanical cabinets and electromechanical components, which guarantees an excellent quality with a reliable operation.

Our cabinets are self-supported, closed or open type with frontal access, lateral or back. made of galvanized or cold steel rolls, in the indicated caliber with mounting plates or slides with auxiliary services accessories, of lighting and heating

- Boards for the handling and power distribution in computer centers,

- Commercial handlings boards for buildings, malls, hospitals

Also we count with equipment for the energy administration, monitoring and power quality diagnosis; electrical projects and services.

Panels Design, Motor Control Center

Design, manufacture and supply Motor Control Center (MCC); The Motor Control Center (MCC) is a board that feeds, controls and protects circuits whose load essentially consists of motors and that use contactors or starters like main control components. The MCC Class I or Class II is provided with wiring; with any of the classes the user can specify the physical adjustment of the units within the Motor Control Center (subject to the design parameters).

The Motors Control Center (subject to the design parameters).normally contain conventional Starters and solid state, frequency variators in AC, Lighting Boards and Transforming, Monitoring Equipment and Control of the Energy, PLC´s with their respective entrances and exits (I/O) and Human-Machine interfaces (HMI). For remote areas, these Motors Control Center can be the control stations and energy distribution in the facilities of Plant.

Electrical protection panels Design

Our experience, flexibility and continuous direction to the client allow us to offer them solutions that satisfy the most specific and demanding applications with the market, like: design and board’s provision and systems from the norms and the operation practices required by the user that guarantee a reliable operation.

Our engineers of schemes design of protection and automation for transmission systems, distribution and generation, selection. Automatizacion Avanzada designs, constructs, assembles, wires, proves the cabinets according to the sector standards

Automation and control panels design

Automatizacion Avanzada S.A. designs, supplies and installs boards for the automation and control of industrial processes, in accordance with its needs, together with pneumatic and hydraulic facilities according to each project.

Our system of industrial control boards for automation, integrates instruments and mechanical devices wired in the plant, such as relays, switches, controllers and auxiliary devices. The control boards can include in their production, compartments to accommodate open industrial control boards or individual industrial control equipments

ENERGY DISTRIBUTION SYSTEM

Motors control center

For the motors the (MSC) it is carried out by the Motors Control Center (MCC), which has the possibility of commanding the motor in remote way and in addition to visualize the different motor states.

Medium voltage electrical substation

For the automatic subsystems sectorial control by PLC’s where the instruments, sensors, motors, of opening and close signals are taken, allows the routines realization, conditions or established programs of the processes of the treatment plant. This control allows controlling the processes of the signals that we have taken to the PLC.

INSTRUMENTATION SYSTEM

Sensorics: Nuestra solución abarca una amplia gama de sensores como son:

Magnetic proximity sensors:

These sensors are for detecting a position, a step, the piece presence, liquid level, speed watching.

Inductive proximity sensors:

The inductive proximity detectors are the preferred choice for the majority of the applications that require reliability, in the detection of metallic objects in the machines without any contact or automation equipments.

Capacitive proximity sensors

The capacitive proximity sensors operate just as the inductive sensors, without contact. The capacitive proximity sensors allow the detection of nonconductive materials and conductive materials, but they are used mainly to detect materials like plastics, liquids, granular plastics, etc.

In the applications with capacitive sensors the sensitivity of these depends on the characteristics of the object material. These metals, plastics, liquids characteristics to detect, influence in the detection range and the commutation point of the sensor.

The capacitive sensors offer a technological alternative for the use in applications where the use of inductive detectors is not possible.

Ultrasonic sensors:

In all the industrial areas in which the environmental conditions like dust, smoke or steam can affect the sensors, the ultrasonic sensors represent the ideal solution for the position determination and the measurement of the distance. The ultrasonic sensors are designed for the detection without contact nor without wearing down of great variety of objects by means of waves in frequency. It is not of importance if the object is transparent or of color, metallic/no-metallic, rigid, liquid or chalking.

Rotating encoders

Rotating encoders can be used in all the applications that require the tracking of: rotation index, speed, acceleration and direction. These sensors can be used in many applications; they are found in mechanical engineering, the transport industry, materials handling and the packing industry. They are used like angle sensors, position, speed and acceleration. Linear movement can also be measured by means of the use of axes, racks arts, the measurement of the wheels or by strip cable Rotating encoders turn a mechanic entrance into electrical signals that can be treated by the accountants, tachometers, industrial PLCs and industrial PCs.

Incremental encoders:

Are those that must pass through a reference mark every time the automation system that they attend, ignites. All the position variations that are made with the disconnected system, will not be taken into account.

Pressure switches:

A pressure switch is a device for electrical control in which the operation of the contacts is performed at a determined pressure of a liquid or gas.

Security detection:

Security carpets: the implantation ensures maximum protection of the operators and the facilities. Designed to detect the intrusion of the operators in dangerous areas.

Machinery Safety:

There are machines with dangerous movements that generate risk to the operators of such equipment, therefore they require systems that provide security in the manipulation, therefore we own the solution:seguridad en la manipulación, por esta razón poseemos la solución:

Security switch:

Designed to protect the machine operators when they open the protection guards, doors or covered to stop the dangerous movements of the machine, we provide solutions for all the client needs.

Security switch:

For explosive atmospheres emergency switches especially designed to work in potentially explosive atmospheres.

¿What is an explosive atmosphere?

According to the directives is the mixture with the air, under atmospheric conditions of flammable substances in the following forms: gas, fog or steam and dust, that in the combustion case, it doesn’t propagate in all the combustion mixture.

Safety Light curtain:

The Light curtains and other optical security mechanisms protect the operators against the dangers of the machinery and the manufacture area, by means the protection of operation points, accesses, areas or unclassified perimeters without sacrificing the production efficiency.

Safety PLCs:

simplify the creation of complex security functions and excellent flexibility when the functions are chosen using the programming software. More precise diagnostics and a better communication with the decentralized execution of I/O security through Ethernet.

For complex machines or automation machines from the lines that require protection for both the operator and the machinery. Automotive sector, carpentry, cement work, packaging, transportation, elevation equipment, semi-conductors, movement control.

Política de Cookies

Este sitio web utiliza cookies, al seguir utilizando este sitio, aceptas nuestro uso de cookies.